Danish wind turbine giant Vestas has announced today that it, along with a coalition of industry and academic leaders, has figured out how to fully recycle wind turbine blades.

Fully recycling wind turbine blades

As Electrek previously reported at the end of April, the University of Strathclyde in Glasgow and Norwegian offshore wind developer Aker Offshore Wind worked out how to recycle glass-reinforced polymer composites (GRP) used in wind turbine blades.

Strathclyde’s Department of Mechanical and Aerospace Engineering developed a solution for thermal recovery and post-treatment process of glass fibers from GRP composites scrap to achieve near-virgin-quality glass fibers.

Now Vestas, along with Olin, an epoxy producer, the Danish Technological Institute, and Aarhus University in Denmark claims to have achieved a full recycling cycle of turbine blades by splitting and recycling both fiber and epoxy:

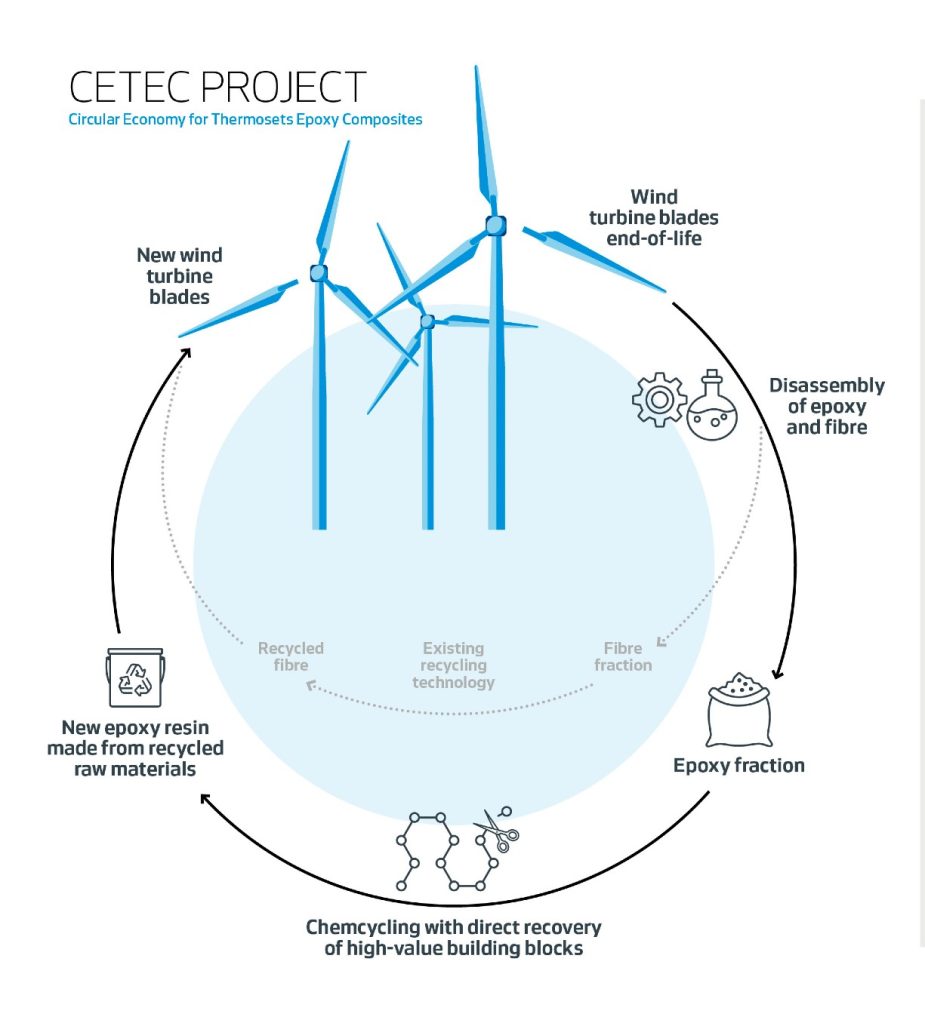

A coalition of industry and academic leaders have developed a new technology to enable circularity for thermoset composites, the material used to make wind turbine blades. The new technology delivers the final technological step on the journey toward a fully recyclable wind turbine value chain. To enable the adoption of this new technology, and to advance a circular economy across the wind industry, a new initiative entitled CETEC (Circular Economy for Thermosets Epoxy Composites) has been established. Within three years, CETEC is aiming to present a fully scoped solution ready for industrial adoption, based on commercialization of the novel circularity technology.

Here’s how the two-step process works. First, thermoset composites are split into fiber and epoxy. Second, the epoxy is further broken up into base components similar to virgin materials using a chemcycling process. These materials can then be reused in new turbine blades. The cycle is illustrated below:

Simon Frølich, PhD, team manager at the Danish Technological Institute, said:

The key characteristic of composite materials is their unique combination of low weight and high strength. This is governed by the strong bonding of two different materials – fiber and epoxy. The dilemma is that this strong bond is also the feature that renders these materials difficult to recycle. Therefore, the development of CETEC’s novel technology, enabling disassembly of the composite at end-of-life, is a gamechanger, that will allow us to capture the value represented by each material stream in a new circular value chain.

The technology also has the potential to be used for components of airplanes and cars.

Electrek’s Take

Advances in the recycling of wind turbines is crucial, because wind turbine manufacturing is ramping up quickly across the globe. The CETEC project is fantastic because it makes wind turbines fully sustainable throughout their life cycle. It also allows manufacturing innovation to move forward without creating landfill as older, less efficient turbines are replaced.

This is an exciting announcement from Vestas just weeks after Strathclyde’s and Aker’s announcement, and we can’t wait to see what comes next.

Photo and graphic: Courtesy of Vestas Wind Systems A/S

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.