I recently took a trip to China in order to see for myself how many of the e-bike drive systems and components we use daily in the West were originally designed and produced. And no journey to view the origins of the most popular e-bike components would be complete without a visit to Ananda, one of the largest and most advanced OEMs in the industry.

I was able to visit the company’s R&D headquarters in Shanghai as well as one of their factory locations in Wuxi, giving me a close look at the design process and how those designs get manufactured into real e-bike systems.

After starting operations in 2001, Ananda has focused purely on micromobility systems since 2011. They’ve long built many types of hub motors for e-bikes and scooters, but expanded into their own mid-drive electric bike motors in 2017. And the company’s scale has grown massively ever since.

You might not have heard of the company yet, largely because they rarely advertise which major e-bike brands use their motors, controllers, and other components. But to put things in perspective, they produced around 6.5 million electric motors last year. Most of their products are built for the massive domestic market, but around 600,000 were exported to Europe and North America, where they made their way onto e-bikes we know and love. Many of the biggest brands use their systems. There’s a good chance you’ve got an Ananda motor, controller, or other hardware in your garage right now and just don’t realize it.

The company is constantly growing and a new Vietnamese factory is currently in the works, but because the North American and European markets are booming for Ananda, the company is currently working on setting up a new European factory. Ananda also recently opened up its first North American service center in Los Angeles and is expanding its local US-based team.

Ananda is responsible for designing and producing just about every component used in an electric bicycle other than the batteries and BMS. However, they work with several battery manufacturers and provide testing to certify compatibility with their extensive drive system lineup.

Their core competency is in research and development, followed by production implementation. While some companies merely design components produced elsewhere and others operate factories to manufacture third-party designs, Ananda does it all in-house, focusing on a wide range of systems ranging from entry-level to premium components.

And while Ananda started as mainly a component maker, offering their own motors and controllers, they’ve since evolved into an entire system integrator. Now they supply many e-bike brands with an entire e-bike system, minus the battery.

That all-encompassing approach has necessitated a huge footprint, with the company touting over 1,000 employees and over 200 automated machines, 70 of which are just for automated coil winding.

Ananda is also one of the most mature mid-drive motor makers in the Chinese market, now developing several higher-power models for the North American market. And with an obvious understanding of what Americans want, they explained to me that all North American motors they develop are compatible with throttles. Talk about knowing your audience!

Touring Ananda’s R&D facility in Shanghai

My tour at Ananda started in the R&D center. There, the company has a team of engineers and designers working on every component of e-bike drive systems.

A major piece of that design and development process is ensuring that each component can withstand the rigors of daily use in the harsh environments that e-bikes and e-scooters experience everyday.

I walked through rows of machines operating every type of torture test you can imagine. I saw motors being heat-shocked with high and low temperatures. I saw tanks with motors undergoing humidity testing, alternating between humid and arid conditions. Rain machines were running to keep a constant spray of water on the components. Each machine looked like a progressively worse type of condition that I’d definitely avoid putting my own e-bike through.

There were robotic button pushers who simply pushed buttons on handlebar displays tens of thousands of times. Motors were shock-loaded to simulate sudden stops and hard braking during operation; Imagine a broomstick in the spokes situation that instantly grinds the motor to a halt.

Dozens of dynamometers were set up for long-term testing, performing months of testing on constantly running motors.

Entire e-bikes were installed in full-scale testing machines to simulate long-term testing of complete systems over tens of thousands of miles.

In other parts of the R&D center, banks of 3D printers whirred away, producing prototypes that may become entirely new drive systems. One such system currently in the works is an e-bike hub motor that includes a three-speed transmission inside the hub. It will essentially become the marriage of a hub motor and an internally geared hub, offering the best of both technologies.

Across the hall, old-school technology in the machine shop contrasts with the high-tech machines, offering no-less-critical machining capabilities for fabricating and modifying new designs.

Teams of bike mechanics install test systems on mule bikes while test riders put them through miles and miles of real-world riding verification.

I even got to have a go myself, donning a company helmet and testing out several of the new motors and drive systems that Ananda has produced. I tried an M100 mid-drive motor that felt like a perfect balance of power and comfort, as well as a more powerful 750W M6100 mid-drive motor that was a lot of fun but, frankly, probably more power than I truly needed most of the time. That model is destined for the US market and is likely to be popular among riders seeking powerful performance.

I even tested a moped-style hub motor system complete with cast wheels that I was sure included a torque sensor in the drive system due to how responsive the pedal assist was. Only afterward did I learn it was actually just a really nicely designed cadence sensor that they had managed to remove almost all the pedal lag from.

After testing the e-bikes, they showed me their new diagnostic tools, which include software designed to easily diagnose issues that could arise over a lifetime of use. Instead of having an unclear error, shops or companies can simply use the software to run checks on the bikes and find out exactly what could be causing a specific issue.

Ananda’s manufacturing facility in Wuxi

The second half of the day was spent at one of Ananda’s factories, where I saw their manufacturing firsthand.

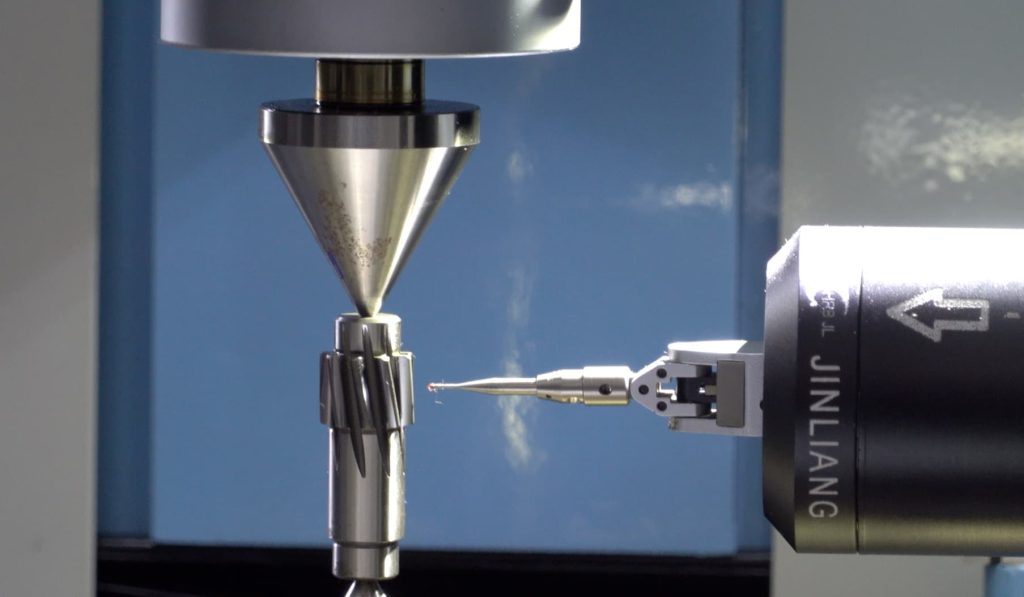

The first step is the inspection and analysis of components from Ananda’s suppliers. Workers inspect these components down to the micron level, ensuring everything is manufactured to spec. Even a small deviation in a motor shell, for example, could result in extra motor noise and increased wear.

That level of precision inspection is what separates the truly high-quality manufacturers who understand the level of accuracy necessary for consistently performing and reliable products.

From there, we moved to the factory floor, where motors are manufactured. The first step is the winding of the motor cores, which involves spools of copper wire being intricately wound around the motor’s stators.

If you’ve ever seen the way electric motors were built in years past, and honestly still in some places, you’ve probably seen videos of women hunched over tables using their delicate fingers for hand-winding motors. But Ananda’s over 70 automated motor winding machines make that a thing of the past.

Now, motor cores are not only wound without human labor, but they’re also done so much more accurately and uniformly. The beauty of robots is that they never make mistakes or get tired and sloppy; they just wind up every single motor the exact same way each time.

Those wound motor cores are then inspected before heading on to the next step of assembly into motor casings. The assembly process is a combination of manual and automated tasks. High-precision jobs, such as placing the gears and building the internal transmissions, are done using robotic assembly machines.

These sub-assemblies are then passed onto the rest of the assembly line, where they are joined by hand with the motor cases. A laser engraver serializes each motor shell along the way, and then it heads to sound testing to ensure it powers up and operates as quietly as it should.

Some motors are assembled using automated machinery, ensuring precision placement of the motor gears and components.

Each finished motor is scanned into the database and then packaged up for shipment to an OEM that will build it into an e-bike, e-scooter, or e-moped. Years ago, e-bike motors were always shipped in foam packaging for protection. But Ananda has switched to much more environmentally responsible paperboard packaging, offering equal protection without using such harmful materials that are not able to biodegrade.

Interestingly, in another part of the factory, I saw many of the same torture testing machines that I had first seen in the R&D center back in Shanghai. As I quickly understood though, this was all part of the quality control process. The same way new designs get torture tested during development in Shanghai, the factory does the same extensive testing as part of spot inspections for each batch of components produced. The motors undergo similar loading and accelerated lifespan testing to ensure they are all performing as intended, and that there aren’t any deviations from one production batch to another.

The next stop was to see how controllers were made, and that involved getting suited up and heading into the company’s clean room facility. There, automated pick and place machines built up circuit boards that then passed through various soldering machines to produce the circuit boards. The process and outputs are all monitored using high-precision 3D optical imaging, allowing the workers to inspect each solder joint from many angles and ensure all the components are properly soldered to the board. Many of these components are too small to inspect with the naked eye, and so this type of imaging and analysis allows the company to ensure every tiny little leg and every minuscule drop of solder is not only correctly placed, but also properly soldered so it doesn’t shake loose 10,000 miles from now.

Next, conformal coating is applied to electronics, creating a waterproof barrier that prevents water vapor from corroding the metals and circuits.

Each of these steps is a small but critical part of the manufacturing process, ensuring that the components produced in Ananda’s factories perform their required functions not just at the start of a product’s life, but also for many years to come.

Rooftop solar array

The last stop of the tour was something I was surprised to see. Before I left the factory, I was led up to the roof where a large solar array gathered much of the energy used by the factory.

While it doesn’t cover 100% of the company’s energy usage, it does offset a large portion and helps to further promote the same message that the electric vehicles using Ananda’s components share: that how we generate and use energy has a major impact on our environment.

These types of steps go a long way to reducing our own harmful effects on the planet. Humans will always need to travel around their cities, and using two-wheeled electric vehicles is one of the most energy-efficient ways to do it. If companies can offset as much of the emissions generated from producing those vehicles, then all the better.

The takeaway

I’ve known of Ananda’s electric motors for years, and in fact built some of my first e-bikes with their motors over a decade ago. But I had no idea how large Ananda had grown and just how much of the entire e-bike system they now produce.

Far from just another e-bike motor manufacturer, Ananda is truly an entire system integrator. Producing everything from displays to controllers and every type of motor you can think of, Ananda has positioned itself as a leader in the micromobility space.

You don’t make 10 million motors a year and several million more controllers and other components without learning a thing or two about how important the quality and precision of those manufacturing processes truly are.

The company has obviously taken all of that learning to heart, developing a high-tech and highly automated design and manufacturing system that has grown into a massive operation.